Intuitively, most people have an understanding of hardness, even if they can’t provide a metallurgically correct definition.

Most people have an idea of strength as well, although most non-technical people may not be aware that any given material has a number of different properties that fall under the category of strength (yield strength, tensile strength, fatigue strength, impact strength, etc.). The terms “hardness” and “strength” may even be conflated for many people.

It is true that hardness and tensile strength correlate fairly well with one another. So, the first question that needs to be addressed is, “Can I use hardness test results to make any judgements on the strength of my material?” The short answer is “Yes” but take it with a grain — or ten thousand — of salt.

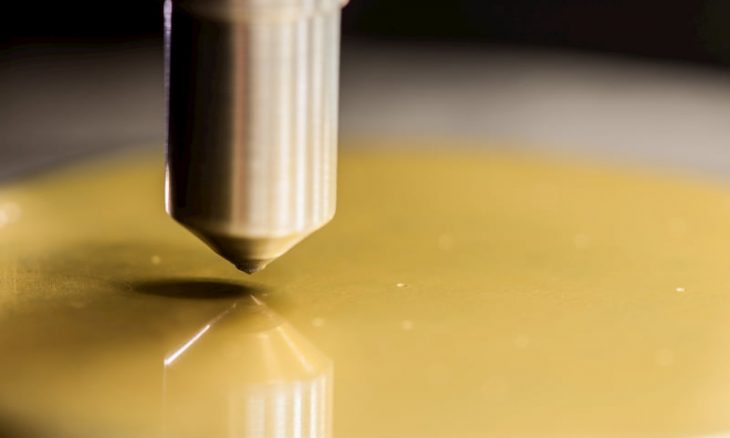

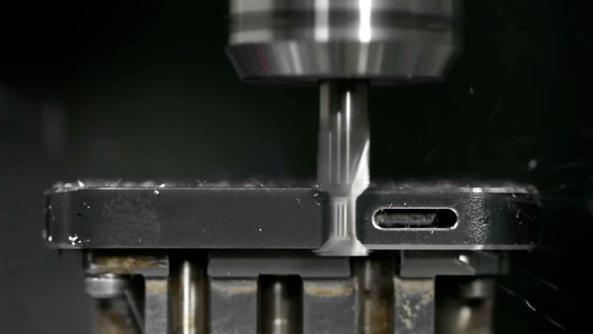

Perhaps it is best to start with the promised metallurgically correct definition of hardness. “Hardness is a material’s resistance to permanent indentation by a given indenter at a particular loading condition.” The bigger and deeper the indentation, the lower the hardness and vice versa. The 3 critical components of the test are the indenter (sharp object pressed into the surface), the load used during the test, and the scale (measurement system used to quantify the results.)

Hardness is really a quasi-mechanical property, as it is actually a function of several other mechanical properties such as elastic modulus, yield strength, and tensile strength, which all influence how far the indenter penetrates under a given load, and how much the material springs back when the indenter is removed. So, there are some other questions that would need to be addressed.

Question: How useful is hardness testing?

Answer: It depends. Done properly, hardness testing can be fairly reliable and repeatable. If not done properly, you will find yourself chasing variation, rejecting good parts, accepting defective parts, etc.

On the positive side:

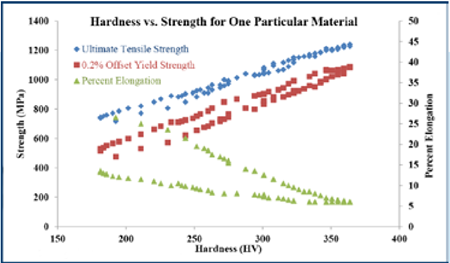

+ Hardness correlates decently to tensile strength, with some scatter (Figure 1).

+ It is the only test one can use to test small, finished parts.

+ If hardness is tested properly and falls within specification, then the other mechanical properties are likely, although not guaranteed, to be within specification as well.

+ Hardness testing may be useful for monitoring processes. As long as the hardness stays consistent, the process is probably within specification as well.

On the negative side:

− Hardness correlates only very loosely to yield strength and ductility, with high scatter (Figure 1).

− Hardness testing has many pitfalls that can lead to inaccurate measurements.

− Even correctly performed hardness tests show wide variation – so it is difficult to determine whether or not the part is within specification.

References

1-https://materion.com/