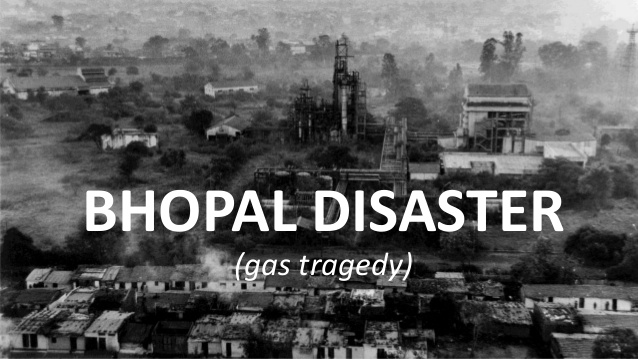

The explosion at the Bhopal Union Carbide factory in 1984 is still the world’s most lethal industrial disaster. It is well established that in its immediate aftermath many thousands of people died as a result of the inhalation of toxic fumes.

Union Carbide chose Bhopal, a city of 900,000 people in the state of Madhya Pradesh, because of its central location and its proximity to a lake and to the country’s vast rail system.

What Happened?

- The plant opened in 1969 and produced the pesticide carbaryl, which was marketed as Sevin/

- Ten years later the plant began manufacturing methyl isocyanate, or MIC, a cheaper but more toxic substance used in the making of pesticides.

- It was MIC gas that was released when water leaked into one of the storage tanks late on the night of Dec. 2, setting off the disaster.

- Gas began escaping from Tank 610 around 10:30 p.m.

- The first effects were felt almost immediately in the vicinity of the plant. As the gas cloud spread into Bhopal proper, residents were awakened to a blinding, vomiting, lung-searing hell. Panic ensued, and hundreds of people died in the chaotic stampede that followed.

- An exact death toll has never been established. Union Carbide, not surprisingly, set the toll on the low end at 3,800, while municipal workers claimed to have cleared at least 15,000 bodies in the immediate aftermath of the accident.

What did it go wrong?

In the night between 2 and 3 December 1984, there was a penetration of large amounts of water into the tank with methyl isocyanate (MIC), with over 40 tons of MIC. The addition of water into the tank caused a runaway chemical reaction, resulting in a rapid rise in pressure and temperature. Heat generated by the reaction, chloroform concentrations higher than normal and the presence of an iron catalyst caused by the corrosion of the stainless steel tank wall, resulted in the opening of the safety valve. Toxic gas composed of MIC, hydrogen cyanide, monomethyl amine, carbon monoxide and other chemicals was released into the atmosphere. The wind blew the cloud of gas and more than 500,000 people were exposed to toxic effects of its ingredients. The parts of the town with dilapidated houses surrounding the plant were most affected, and the victims were exclusively from poor communities.

The official death toll is 2,259, while unofficially the number is much higher, about 8,000.

Many researchers and scientists have agreed that the corrosion of the pipelines and other safety equipment are the main culprit for this disaster.

According to the Accident Investigation;

– MIC was stored in three double-walled stainless steel tanks, codenamed 610, 611 and 619. One of the third shift workers noticed that the pressure in tank 610 (the tank from which all MIC leaked) increased from 2 psi as it had been recorded one hour before, in the previous shift, to about 10 psi. Pressure increase for more than five times in an hour was not taken seriously because of the belief that the instrument for measuring pressure was faulty. Shakil Qureshi, the supervisor on duty, said later: “The instruments were often not working. They were corroded.”

– Theheat released by the reaction of water and MIC raised the temperature in the tank. At the same time, the reaction was accelerated by iron as a catalyst, resulting from the corrosion of the tank wall under the influence

of high temperatures. The UCIL claimed that the corrosion rate was significantly increased due to the presence of an incredibly high level of chloroform. The rapid release of carbon dioxide in large quantities then

helped to build up high pressures, which forced the foaming mass of chemicals out of the tank.

– The final blow was the fact that the tower designed to burn MIC was not usable due to the corrosion of a pipe which had not been replaced.

After the Accident

The aftermath of the disaster was almost as chaotic. Union Carbide was initially responsive, rushing aid and money to Bhopal. Nevertheless, faced with a $3 billion lawsuit, the company dug in. It eventually agreed to a $470 million settlement, a mere 15 percent of the original claim. In any case, very little money ever reached the victims of the disaster.

In June 2010, seven former employees of Union Carbide’s Indian subsidiary were found guilty of death by negligence. They were fined about $2,000 each and sentenced to two years’ imprisonment, then released on bail.

The victims of the disaster, those who live on, continue dealing with various health problems — including chronic respiratory problems, vision problems and an increased incidence of cancer and birth defects — and an environment that remains contaminated to this day.